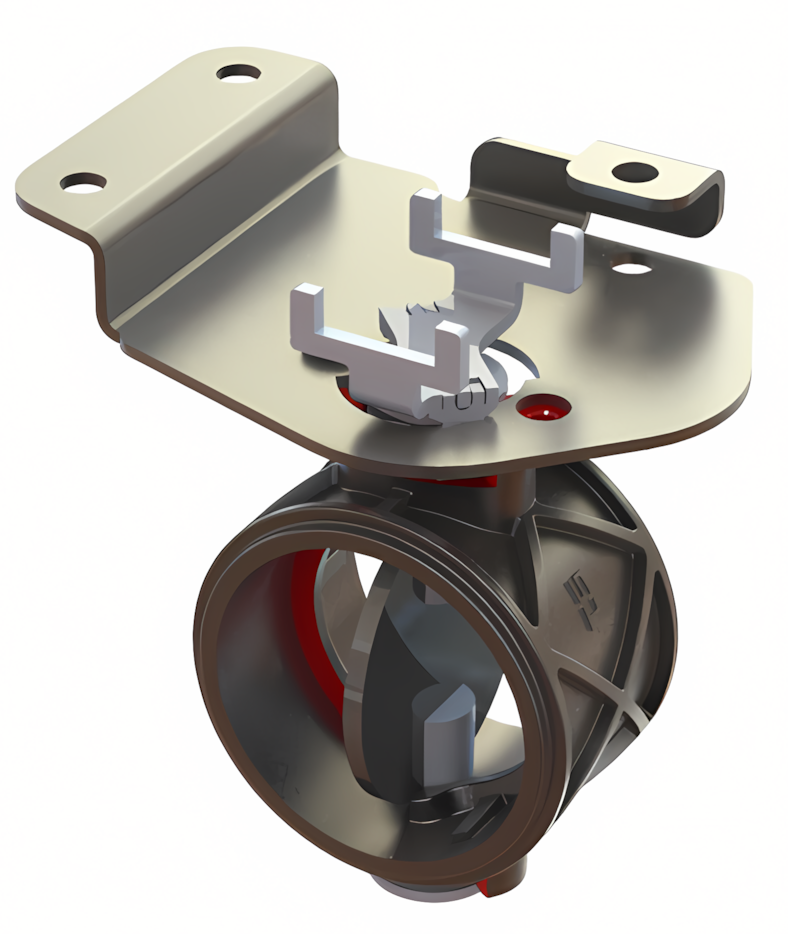

Exhaust flap AR4 - S3 (SBS Camaro)

Product number: A-011-096€261.80*

0193ad4fcc0073d5ac245a098845cf5b

Our AR2 series exhaust flaps are available in seven different sizes as standard, with inner diameters ranging from 51 to 89 mm.

They have been specifically designed for use in the middle and rear silencer areas and impress with their high reliability. The maximum operating temperature is up to 350 °C (short-term).

Compatibility and Use

Compatibility

The S3 adaptation is suitable for actuators from the company SBS.

Used by the following manufacturers, among others: Chevrolet - Camaro / Corvette (old)

Use

The actuator is simply placed on top of our exhaust flap and screwed in.

Please check compatibility using the images! The actuator is not included in the scope of delivery.

Advantages

Material

We use only stainless steel of specification 1.4828 for the base body.

Construction

Our exhaust flaps are designed by us in Germany.

Manufacturing

The manufacturing of our exhaust flaps is done on CNC turning and milling machines 100 percent in Germany.

Notes

Since an exhaust flap is a product with very diverse application possibilities, it is not possible for us to define its usability based solely on simple parameters. For this reason, the following information must be strictly observed before using our exhaust flaps.

The usability must be thoroughly tested by the exhaust system manufacturer. We generally do not grant approval for applications that have not been substantiated by a defined test run submitted to us. In the test run, the load must be demonstrated over at least 20,000 real driven kilometers. The tested exhaust flap must then be sent in for examination to apply for approval. We generally accept no liability should a flap mechanism fail or cause noise due to disregard of the notes.

Maximum exhaust temperature: 350°C (short-term)

Maximum pressure: 0.5 bar (short-term)